Ultrapure Water for the Life Sciences Industry

Pharmaceutical, Life Science, and R&D Applications

While tap water is treated to a high standard to render it safe to drink, it can still contain harmless contaminants and impurities that can negatively affect the accuracy of laboratory research, clinical tests and analyses, and the quality of pharmaceutical products. Therefore, laboratory water must be purified further to remove all impurities from the water.

Some common research, pharmaceutical, and clinical applications where high-purity water is required include:

Cell and Tissue Cultures: When cells are grown in an artificial, controlled environment, the cell culture has to be provided with nutrients and water to sustain its growth, so contamination must be avoided at all costs. Ultrapure water can achieve this without contaminating the cultured cells with potentially harmful pollutants such as bacteria, endotoxins, and heavy metals (ions).

DNA Sequencing: During the DNA sequencing process, the water used must meet stringent quality standards. Contaminants that can disrupt the DNA sequencing process or negatively impact results include nuclease, organic matter, ions, and bacteria.

Liquid or Gas Chromatography: Chromatography is a powerful analytical tool used to identify components in a mixture. Ultrapure water is used as a reagent because it’s free of impurities like organic compounds, ions, bacteria, and particulates that can produce background noise, negatively impacting the results.

Pharmaceutical Production: Ultrapure water is a key ingredient in manufacturing pharmaceutical products. It prevents contamination and ensures the integrity of ingredients so the final product remains effective and safe to use. Ultrapure water is essential for laboratory testing procedures and quality control. It is used to dilute samples, calibrate instruments, and clean and sterilize laboratory equipment and surfaces.

The MASTERpak™ MICRO is a small ultrapure water treatment system that packs a big punch

MECO’s MASTERpak™ MICRO system produces ultrapure water that exceeds global pharmacopeia standards, including most lab water standards, and can also meet standards for ambient water for injection.

MASTERpak™ MICRO offers several benefits to the life sciences industry:

- Reduced water and energy consumption.

- Reduced OPEX for chemicals, water, and electricity.

- Reduced square footage.

- Reduced risk of biological loop contamination and potential product contamination.

These factors result in improved environmental performance, which along with a reduction in capital outlay and operating costs, enhances both environmental and economic sustainability.

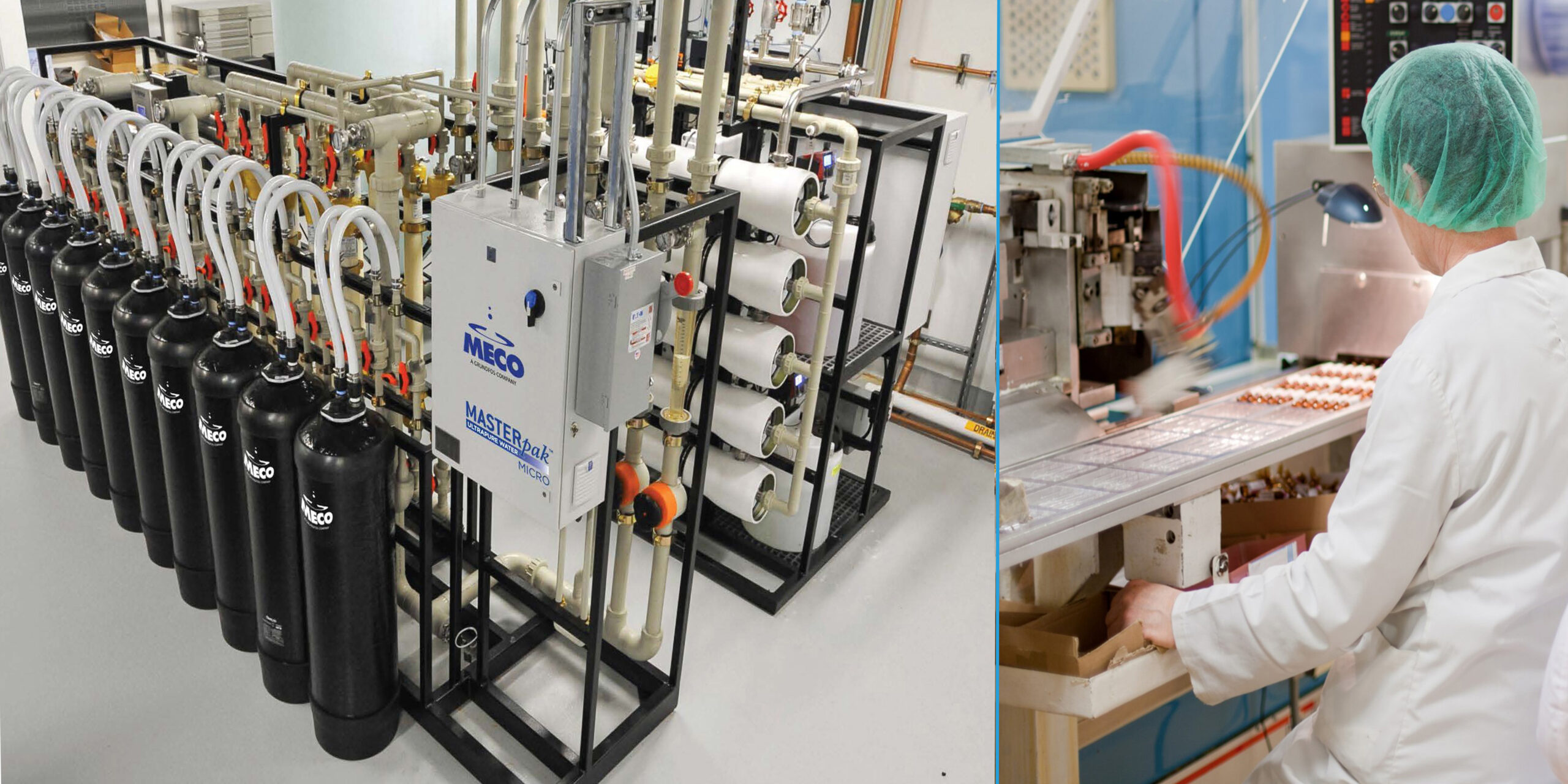

The MASTERpak™ MICRO unifies loop operation and makeup operation into one simple system customized to your plant requirements. It can handle multiple loops with flows from 5 to 100 GPM and can meet production demands up to 100 GPM.

MECO’s full range of on-site services, including service deionization tanks regenerated in a USP-dedicated plant, eliminates the risk of loop contamination from co-mixing resin with an industrial or water reuse application.

THE MASTERpak™ MICRO ULTRAPURE WATER SYSTEM

Environmental Savings

The design of MASTERpak™ MICRO saves water and energy with efficient membranes, simplified design, and maximum water recovery. Our team applies its extensive experience in membrane purification to design drought and conservation-focused solutions, from 100% reverse osmosis recovery systems to dynamically operated cooling and softening systems, which save millions of gallons of water per year.

60% More Water in 50% Less Space

The MASTERpak™ MICRO boasts an integrated design that eliminates nonessential components and reduces its footprint by more than 40%. Every pipe connection is an infrared-certified weld, which saves inches on more than 200 connections, reducing footprint with cleaner connections and less biofilm risk. With a smaller footprint, you can put your Ultrapure Water system just about anywhere.

Save space, reduce biofilm risk, and produce 60% more water with the MASTERpak™ MICRO.

A Holistic Approach to Sustainability

Our approach to water conservation goes beyond just being water-wise. We perform a thorough economic analysis for each installation, considering our customers’ operational and growth needs and the costs of capital, operation, optional validation, and maintenance. We strive to maintain a competitive edge by investing in the latest manufacturing technologies and top engineering talent while ensuring that the quality of our work is never compromised.

Contact MECO for Ultrapure Water Systems

MECO is committed to being a comprehensive solutions provider to the life sciences industry, and our MASTERpak™ MICRO ultrapure water systems and services are a testament to that. Our system is designed to produce water that surpasses global pharmacopeia standards in a sustainable manner. To find out more about our water purification solutions and services, please CONTACT MECO today.