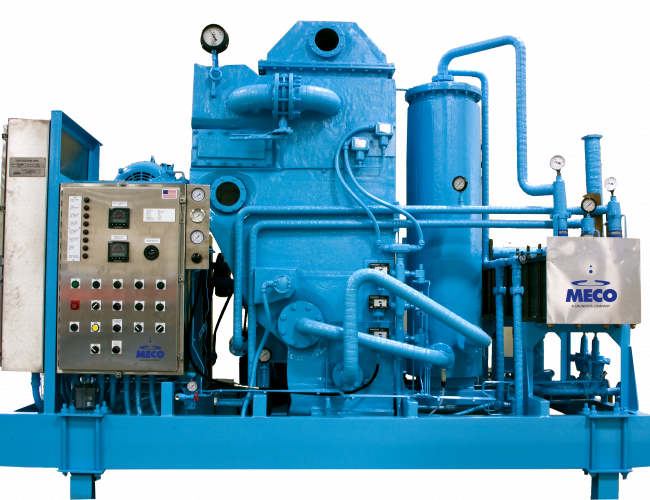

In 1939, MECO patented the mechanical vapor compression process for the desalination of saltwater. Since then, we’ve refined and improved the technology to deliver high-quality potable drinking water and distilled water in some of the world’s harshest environments. With MECO, you get a completely packaged unit that features the surface preparation and coatings suitable for the marine environment. Plus, the units require minimum field installation. And since MECO has installations worldwide, you have access to a global service network that can respond quickly to emergencies and service maintenance needs.

| MODEL | CAPACITY in GPD [m3/day] |

|---|---|

| PEE300M3C | 7,200 [27] |

| PEE400M3C | 9,600 [36] |

| PEE600M3C | 14,400 [55] |

| PEE800M3C | 18,500 [70] |

| PEE1250M3C | 30,000 [114] |

Notes: Capacities are based on seawater with a TDS of 35,000 ppm at 77°F (25°C). MECO M3C units typically operate based on a concentration ratio of 1.77.