How Is Green Hydrogen Produced?

For years, we’ve been hearing about hydrogen as a fuel. Because it acts as an energy carrier, not a primary power source, its impact on greenhouse gas emissions varies depending on whether or not it’s produced using carbon-based fuels.

Enter green hydrogen. This revolutionary fuel has immense promise in mitigating climate change and reducing our dependence on fossil fuels because it’s produced using renewable energy sources like solar, wind, or hydroelectric power.

Green hydrogen is generated with an environmentally friendly process. During electrolysis, water is split into its constituent elements, gaseous hydrogen, and oxygen, and the hydrogen gas is captured and stored for various applications.

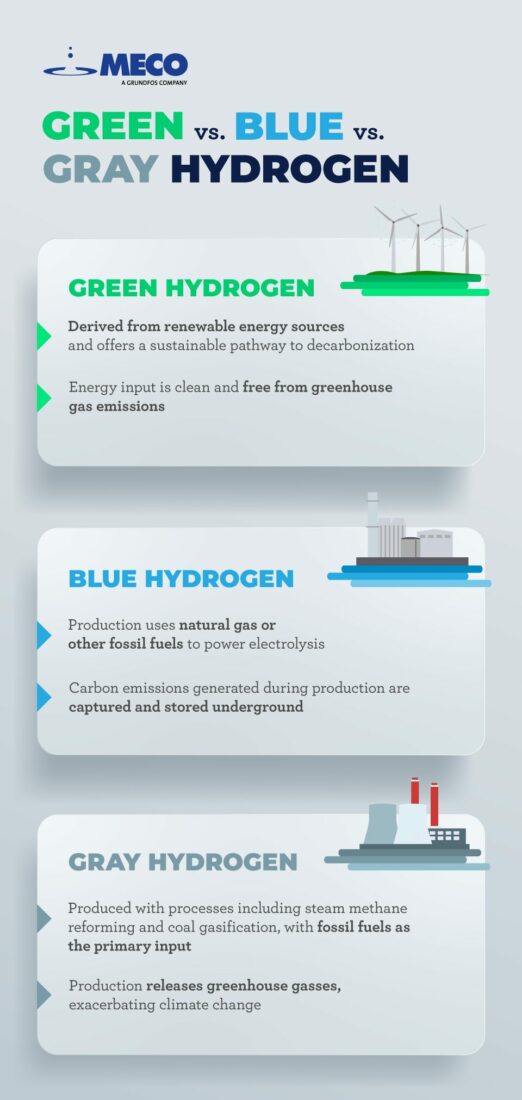

Green Hydrogen Versus Blue or Gray Hydrogen

How is the production of green hydrogen different than other methods? Green hydrogen is produced using only renewable energy sources, ensuring zero carbon emissions throughout its life cycle. In comparison, blue and gray hydrogen are generated using fossil fuels such as natural gas or coal.

Green Hydrogen

Green hydrogen works through electrolysis, a process used to produce it relies solely on electricity generated from renewable sources like solar, wind, or hydroelectric power. It is derived from renewable energy sources and offers a sustainable pathway to decarbonization.

The process ensures the energy input is clean and free from greenhouse gas emissions. As a result, the entire lifecycle of green hydrogen, from production to utilization, is characterized by minimal environmental impact.

Blue Hydrogen

Blue hydrogen production uses natural gas or other fossil fuels to power electrolysis. However, the carbon emissions generated during production are captured and stored underground, preventing them from being released into the atmosphere. While blue hydrogen has a lower carbon footprint than gray hydrogen, it still relies on fossil fuels.

Gray Hydrogen

Gray hydrogen is produced with processes including steam methane reforming and coal gasification, with fossil fuels as the primary input. The process releases carbon dioxide emissions into the atmosphere without carbon capture or storage. As a result, gray hydrogen production releases greenhouse gases, exacerbating climate change.

Environmental and Sustainability Benefits

When green hydrogen is produced, the only byproduct is water vapor, making it a sustainable energy carrier. This makes green hydrogen a compelling solution for reducing greenhouse gas emissions in traditionally hard-to-decarbonize sectors like heavy industry and transportation.

The versatility of green hydrogen extends to various sectors. It can be used as a clean transportation fuel, powering fuel cell electric vehicles and eliminating harmful tailpipe emissions. Additionally, green hydrogen can be employed in power generation, providing a sustainable alternative to fossil fuels. It can also be used as a feedstock in industrial processes, replacing carbon-intensive materials and reducing the industries’ overall carbon footprints.

Hydrogen Electrolysis

During the electrolysis process, water is separated into gaseous hydrogen and oxygen in specialized facilities known as green hydrogen production plants.

- Transforming water into clean hydrogen: The electrolysis process begins with the preparation of water as the input material. To ensure the quality of the resulting hydrogen gas, high-purity water is introduced into the electrolyzer device.

- Types of electrolyzers: Two main types of electrolyzers are used in green hydrogen production: alkaline electrolyzers, which use a liquid alkaline electrolyte, typically potassium hydroxide, and proton exchange membrane (PEM) electrolyzers, which use a solid polymer membrane as the electrolyte.

- Electrolysis cell configuration and design: Electrolysis cells consist of an anode and a cathode separated by the electrolyte. The anode and cathode are typically made of specialized materials, such as nickel or platinum, that can withstand the harsh conditions of electrolysis.

- Electrochemical reactions: During the electrolysis process, electrochemical reactions occur at the anode and cathode. As electricity is applied to these electrodes, water molecules lose electrons at the anode, forming oxygen gas and positively charged hydrogen ions. Simultaneously, the hydrogen ions gain electrons at the cathode, producing hydrogen gas.

- Generation of output: As the electrolysis process continues, hydrogen gas is collected at the cathode, while oxygen gas is collected at the anode. The hydrogen gas can then be captured, stored, and used for various green hydrogen products, such as fuel for hydrogen fuel cell vehicles or providing a clean energy source for industrial processes.

Energizing Green Hydrogen Production

In a green hydrogen production plant, the power source used for electrolysis determines the sustainability and environmental impact of the process. Green hydrogen is produced using electricity from renewable energy sources, making it a key enabler of a clean and sustainable energy future.

- Solar power: Solar power is a renewable energy source that harnesses the energy of sunlight through photovoltaic panels or solar thermal systems. In a green hydrogen production plant, solar panels can be installed to capture solar energy and convert it into electricity.

- Wind power: Another renewable machine to produce green hydrogen production is wind power. Strategically positioned in areas with strong and consistent winds, wind turbines generate electricity as their blades capture the wind’s kinetic energy.

- Hydroelectric power: Hydroelectric power harnesses the energy of flowing or falling water to generate electricity. In this approach, water stored in reservoirs is released, and the force of the water’s movement turns turbines, producing electrical energy.

Energy Storage Integration

Energy storage systems store excess electricity generated by renewable sources during periods of high generation and supply it to the electrolyzers when renewable energy generation is low or intermittent.

- Battery energy storage: Battery energy storage systems store the surplus electricity generated from renewable sources and discharge it when the demand for electricity in the green hydrogen production plant exceeds its current generation capacity.

- Hydrogen storage: Besides storing excess electricity, the produced green hydrogen can also be stored for future use. Green Hydrogen storage systems, such as compressed hydrogen tanks or underground caverns, provide a means to store large quantities of green hydrogen.

Scaling Green Hydrogen Production

Scaling commercial water electrolyzers for green hydrogen production involves exploring various production methods, including centralized and distributed approaches. Each method has advantages, and the choice depends on considerations such as resource availability, infrastructure development, and regional energy needs.

- Centralized green hydrogen production: In the centralized approach, large-scale electrolyzer plants are established strategically, often near renewable energy sources. These plants are designed to produce substantial volumes of green hydrogen to meet the demands of multiple industries and sectors.

- Distributed green hydrogen production: In contrast, distributed green hydrogen production involves smaller-scale water electrolysis machine installations located closer to the end users or within specific industrial complexes. This approach allows for more localized hydrogen production, reducing transportation and distribution costs.

Integration and Collaboration

Scaling green hydrogen production requires collaboration among stakeholders, including governments, industry players, research institutions, and investors.

- Infrastructure development: Developing a comprehensive hydrogen infrastructure includes hydrogen storage facilities, transport networks, and refueling stations for transportation applications. Collaboration among industry participants, governments, and infrastructure developers is essential to ensure the timely and coordinated expansion of the hydrogen ecosystem.

- Research and development: Continued research and development efforts are vital to advance industrial water electrolysis systems and technologies to improve efficiency, reduce costs, and enhance the overall performance of green hydrogen production. Investments in innovation, materials science, and process optimization can drive technological breakthroughs, making green hydrogen more economically viable and accelerating its adoption across industries.

Contact MECO Today

As the demand for green hydrogen rises, harnessing renewable energy sources and employing advanced hydrogen electrolyzer designs will make the scaling of green hydrogen production achievable.

With our extensive experience in water purification and commitment to building strong customer relationships, MECO is well-positioned to contribute to this transformative industry. Contact our team of experts today to explore how MECO can support green hydrogen production needs and help navigate the path toward sustainable green hydrogen production.