Improving the Efficiency of Water Distillation Equipment

Water distillation is a vital step in the water purification process for many industries and organizations. Pharmaceutical organizations rely on water distillation to meet industry safety standards, while the food and beverage industry can use use this technique to ensure their product ingredients are safe for consumption. Industrial companies can benefit from the comprehensive particle and chemical removal that water distillation offers for cleaner processes. Continue reading to discover how companies can improve their distillation process.

Why Are Efficient Water Distillation Equipment and Processes Important?

Maintaining optimal equipment efficiency is essential for all machinery. When an organization’s water distiller efficiency can impact many other processes and equipment, understanding why it is important to improve efficiency can motivate organizations to integrate new strategies and techniques. Some benefits of efficient water distillation include:

- Increasing production efficiency: When organizations rely on distilled water to run equipment or manufacture products, an efficient water distiller can ensure overall processes run smoothly and quickly. Further, companies can make more products with an efficient distiller in the same amount of time, allowing them to meet demands better and improve other business processes.

- Optimizing equipment life span: Manufacturers calculate equipment life spans by determining how long they will efficiently function. When inefficient processes overwork water distillation equipment, they can experience more wear than they would otherwise. Companies can optimize their equipment usage and ownership by implementing strategies that support efficiency for products that work better for longer.

- Reducing maintenance: When inefficient processes overwork and wear equipment, companies might have to increase how frequently they service or repair their equipment. Parts might need replacing sooner, and underperforming components can further strain others. Efficient water distillation can protect equipment quality and ensure companies can continue operating longer without breaks or stalls for repairs and parts arrivals.

- Maintaining supply chain efficiency: While production efficiency is essential for meeting demand, companies can use this metric to preserve partnerships and further meet customer expectations. More efficient equipment is more reliable because it will require less maintenance and repairs, meaning companies can give customers, distributors, and warehouses more accurate solutions about when they will receive goods. Clearer communication efforts and accurate delivery information foster stronger relationships across the supply chain.

Functional distillation equipment is crucial to maintaining an organization’s efficient operations. When all parts and components can work at their best, companies can reap the full benefits of their equipment and investments.

How to Increase Water Distillation Equipment Efficiency

When companies want to improve process efficiency, they will need the right strategies. Implementing these techniques will ensure organizations can optimize their water distillation equipment for better results and increased benefits.

1. Clean Equipment Regularly

An organization’s water distillation equipment removes many substances from water sources, from chemicals like chlorine to dangerous chemicals. These materials can build up over time, especially in heating and boiling chambers, to disrupt functions and decrease efficiency.

Scale is usually from excess calcium and magnesium in water sources, which can layer in water purification systems like distillation equipment. As the scale grows thicker, it can impact how efficiently the water boils. Heaters will have to work harder to affect the water through the scale that grows on the sides and bottom of water chambers and heat sources. Overheating can increase costs for organizations while overworking equipment, decreasing its functionality and life span.

Regularly treating water systems to prevent excess scale buildup can save the equipment from overworking and overheating. Investing in a cleaning solution can break down the scale and wash it from the heating chamber, but regularly emptying water can help clear out the scale before it becomes excessive.

2. Conduct Preventative Maintenance

In addition to cleaning to prevent buildup, you can protect your water treatment systems and equipment with regular maintenance and preventative testing. This maintenance type can identify wear and potential problems before they require expensive and extensive repairs, preserving the overall quality of your equipment. Even small problems can impact the performance and functionality of other equipment components, causing them to overwork and wear faster.

Because you must schedule maintenance, you can better account for shutdowns and operation pauses. Unmaintained equipment can fail unexpectantly, impacting other water treatment tools in your system and putting strain on them. You can lose valuable time and funds waiting for repairs and parts.

MECO can help your organization maintain its water treatment systems in our parts and service department. This team comprises certified and highly trained technicians who can perform on-site preventative maintenance and other repairs.

3. Invest in Soft Water Solutions

Hard water is high in minerals that result in equipment scale. Alternatively, soft water is free of harsh minerals that can impact the distillation processes. When companies want to promote distillation efficiency, using soft water can reduce strain on the equipment and prevent scale buildup at its source.

While some places might be able to access soft water naturally, water hardness can depend on region and previous treatment processes. Many organizations use water deionization to produce soft water for more efficient and advanced water solutions. MECO offers a comprehensive line of water softeners to remove hardness, ammonia, or both, and they are designed for various applications and water qualities. We constructed these efficient and high-performance models with quality materials for improved functionality.

Also called ion exchanging or demineralization, deionization removes salt and minerals from water by exchanging ions to change properties. This process is very effective and results in soft water which can be distilled through purification processes to reduce scale buildup. Deionized water has many applications but only removes minerals and does not have the extensive purification that comes with distillation.

Water Distillation Equipment Applications in Various Industries

Water distillation is a versatile process that has many applications across industries. Many individuals own personal distillers in their homes to improve their water supply, but businesses can use commercial and industrial water distillers in various processes.

1. Pharmaceutical

Pharmaceutical organizations rely on water purification processes to create safe products for medical professionals and produce life-saving medications. In this industry, distilled water functions in water for injection (WFI) applications. Pharmaceutical companies will use distilled water to create injectable medications and sterile implantable medical devices. Distilled water is also crucial in cleaning processes to ensure sterile medical environments.

2. Food

The food industry needs to create safe foods and drinks that individuals can count on to consume safely. Distilled water functions as a vital ingredient in many products. Producers can better ensure health with this comprehensive water purification process that removes chemicals, compounds, and other hazardous substances.

3. Industrial

The industrial sector applies distillation to several project types and processes. Organizations might include distillation in their wastewater treatment process to ensure water returns to sources clean and free of contamination. Chemical plants and mining operations use distilled water to run equipment and ensure sterile environments.

Experience Optimized Efficiency With MECO Distillation Equipment

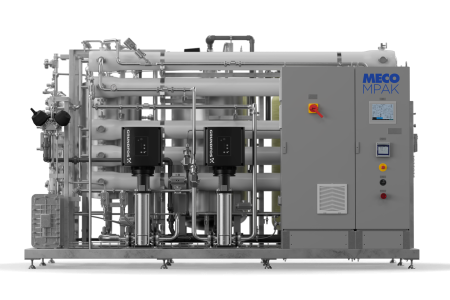

Organizations can boost their water distillation efficiency with the right strategies and practices, but they can also support processes with equipment designed for optimized operations. With over 90 years of experience, MECO is a leader and trusted name in water purification solutions.

We manufactured our water distillation equipment with materials designed to reduce scaling and bio-growth for increased efficiency and better results. Our models have the suitable capacity and configuration for commercial and industrial applications, allowing companies to operate at a level that meets their efficiency standards. They can deliver products and complete processes at the speed and scale they need to stay successful in their industry.

Contact MECO today and discover how our equipment can improve water distillation efficiency.