Everything to Know About Reverse Osmosis Membranes

Over the last few years, there has been an increased demand for reverse osmosis membranes in water treatment. The drive in this market has resulted from developing government regulations placing new restrictions on the treatment of municipal and industrial water and growing conservation methods due to water scarcity. The global market for reverse osmosis membranes in 2021 reached USD 3.1 billion and is projected to reach USD 5 billion by 2026.

This increased demand will soon hit many industries that rely on water purification for production, so facilities need to know why reverse osmosis systems are so critical. This guide discusses everything about reverse osmosis, including how it works and why so many industries rely on this critical process.

What Is Osmosis?

It’s important to know how osmosis works to understand the process of reverse osmosis. Osmosis is a naturally occurring process that refers to the movement of water molecules from a weaker saline solution with a high concentration of water molecules to a stronger saline solution with a lower concentration of water molecules.

This biological procedure occurs through the cell’s partially permeable membrane, which allows certain ions, like liquids and gases, to pass through. Essentially, solutions with less concentration naturally tend to migrate to a higher concentration solution during osmosis. An example of osmosis in nature is when plants and foliage absorb water through the soil. In humans, kidneys also use osmosis to absorb water from the blood to filter out toxins.

What Is a Reverse Osmosis Membrane?

Like osmosis, reverse osmosis also uses a partially permeable membrane — also known as a semi-permeable membrane. This membrane prevents certain molecules and atoms from migrating while allowing others to pass through. Consider a semi-permeable membrane like a screen door.

While air molecules can get through with no problem, anything larger than the holes in the screen will not be able to pass. In reverse osmosis, water molecules can pass through the membrane, but not dissolved salts, pyrogens, organics, bacteria, and other molecules. Most reverse osmosis membranes are composed of a thin film composite membrane. These non-porous membranes typically have three layers:

- Polyester support web

- Microporous polysulfone interlayer

- Ultrathin polyamide barrier layer

Reverse osmosis membranes are critical for producing freshwater through purification by filtering out contaminants and other large dissolved molecules. This process is also used for handling water in the manufacturing, waste, food, pharmaceutical, medical, and wastewater industries.

How Reverse Osmosis Works

Reverse osmosis, as the name implies, is the process of osmosis in reverse. This water filtration technique uses a semi-permeable membrane to remove impurities from water and generate highly purified water necessary for any applications, such as:

- Industrial boilers

- Drinking water systems

- Pharmaceutical production

- Food and beverage processing

While osmosis occurs naturally, reverse osmosis requires applied energy. This energy allows the membrane to overcome osmotic pressure. The result of this process is that the solute and other impurities are retained on the highly pressurized side of the semi-permeable membrane, and the pure solvent is allowed to pass to the other side.

Reverse osmosis systems apply a higher pressure than osmotic pressure and force the water through the reverse osmosis membrane to desalinate the water. This allows the pure water to flow through while holding back most contaminants.

What Do Reverse Osmosis Systems Do?

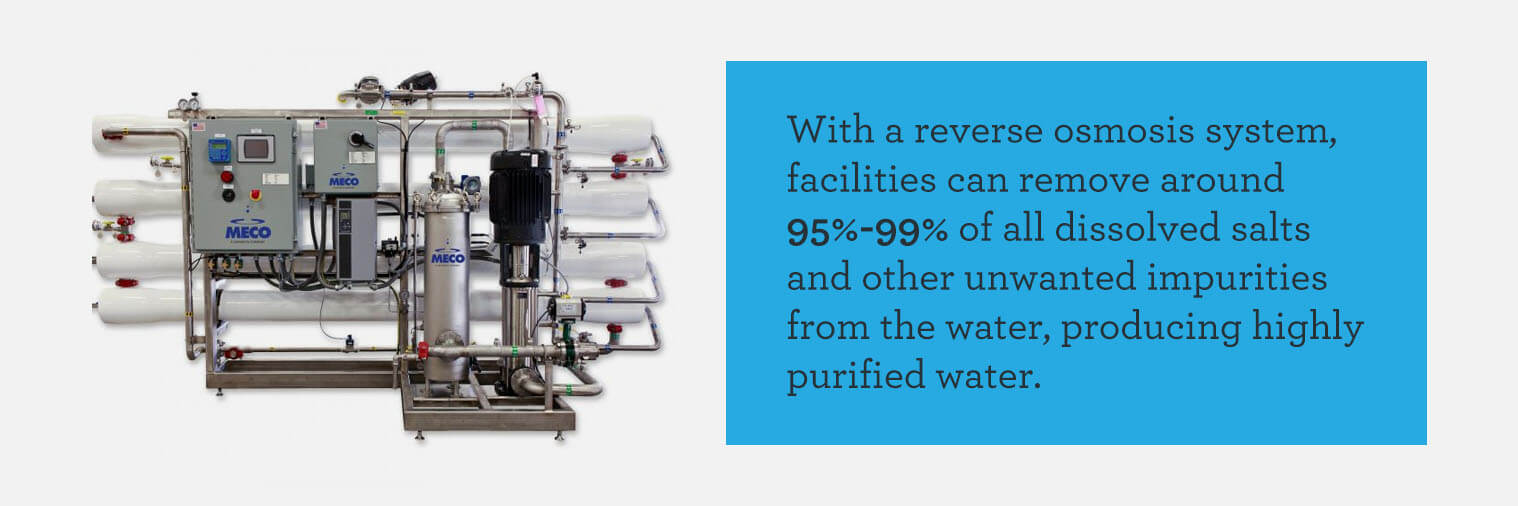

Reverse osmosis systems allow this process to occur within a facility that requires purified water for various applications. These systems use high-pressure pumps to create the pressure needed on the salt side of the reverse osmosis system and push the water across the semi-permeable membrane. In this system, reverse osmosis can occur while collecting the dissolved salts in the reject stream so purified water can be used quickly and efficiently.

The desalinated water — also called demineralized or deionized water — becomes permeate or product water, which can then be used for several production needs. Once all the water goes through the reverse osmosis membrane under pressure, the reject water with the contaminants can be disposed of or can be recycled back into the feed water supply in some cases.

Water conservation and sustainability are important in many commercial and industrial applications, so some facilities purify more water than others. Reverse osmosis systems make this process much easier by using cross-filtration and outlets to avoid the buildup of contaminants and keep the semi-permeable membrane’s surface clean.

Reserve osmosis systems make it easier for users to find the right amount of pressure before conducting the process. For example, users may need to apply more or less pressure depending on the salt concentration or contamination of the feed water. The higher the concentration, the more pressure is required to overcome osmotic pressure, and vice versa. With a reverse osmosis system, facilities can remove around 95%-99% of all dissolved salts and other unwanted impurities from the water, producing highly purified water.

Benefits of Reverse Osmosis

As a water purification process, reverse osmosis provides many advantages. The primary benefit of this treatment is to remove a wide range of bacteria, contaminants, and other dissolved solids from water, including:

- Lead

- Dyes

- Nickel

- Barium

- Arsenic

- Sodium

- Calcium

- Fluoride

- Mercury

- Chlorine

- Sulfates

- Sediment

- Pesticides

- Phosphates

Some filtration systems that perform reverse osmosis can also remove organic contaminants like certain viruses. Other benefits to reverse osmosis include:

- Cost-effectiveness: Reverse osmosis is a common treatment used in many industrial settings because it’s relatively affordable compared to other water filtration methods and treats large volumes of water.

- Eco-friendliness: Unlike alternative water treatment methods, such as thermal distillation, reverse osmosis is also more environmentally friendly because it uses less energy. Reverse osmosis systems can help facilities reduce their carbon footprint and do their part to protect the environment.

- Hardness and alkalinity removal: Reverse osmosis removes magnesium and calcium ions that cause hard water and carbonate ions that contribute to excessive alkalinity.

- Dissolved solids reduction: While a few treatment methods can help reduce dissolved solids, none are as effective and efficient as reverse osmosis, which reduces these solids and other unwanted particles.

Discover Reverse Osmosis Systems From MECO

Thousands of plants, facilities, and treatment centers around the world need reliable reverse osmosis systems and powerfully engineered products to generate clean water. At MECO, we proudly serve the pharmaceutical, biopharm, and many other industries with sustainable water purification technologies.

We are a trusted world leader in water purification solutions with over 90 years of experience. Our mission is to develop innovative technologies and solutions that make water purification more accessible for the many industries we serve and beyond. Our highly experienced engineers and wide range of products make it possible to adjust to any water requirements and operational needs. Get in touch with us today to learn more about our commitment to the future of water.