Ultrapure Water for University Research and Development

Many academic disciplines depend on a reliable supply of ultrapure water

From the precise experiments in chemistry labs to the delicate cell cultures in biology research, the demand for water free of contaminants is universal. In physics and engineering, where precision is paramount, ultrapure water ensures the accuracy of measurements and the reliability of experiments. Moreover, in environmental science, the need for uncontaminated water is crucial when studying ecosystems and their intricate dynamics. The versatility of ultrapure water extends across diverse fields, highlighting its pivotal role in maintaining the integrity and credibility of academic research across the scientific spectrum.

In university research and development laboratories, water must be free of bacteria, organic matter, mineral ions, and other impurities that can contaminate samples and compromise results. Because ultrapure water is free of these impurities, it’s used in a wide range of applications.

What Is Ultrapure Water?

Ultrapure water (UPW) is water that has been purified to meet stringent specifications. It must contain no contaminants such as organic and inorganic compounds, volatile and nonvolatile substances, dissolved and particulate matter, dissolved gases, and hydrophilic and hydrophobic substances. What’s left is simply pure water, made up of equal amounts of hydrogen and hydroxide ions.

Because it is so highly purified, the absence of minerals and other contaminants results in ultrapure water having a neutral pH, making it a weak conductor of electricity. The lack of minerals and impurities gives ultrapure water a highly transparent and colorless appearance, and it is also tasteless and odorless.

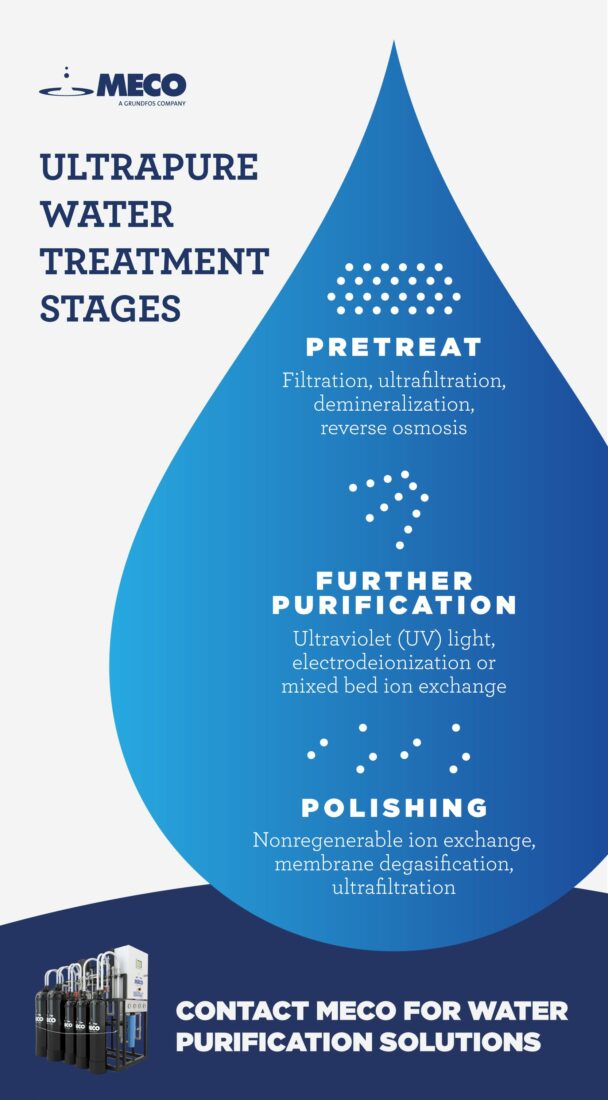

Ultrapure water treatment typically consists of three stages:

- A pretreatment stage that produces purified water with processes including filtration and ultrafiltration, demineralization, and reverse osmosis.

- A stage that further purifies the water with processes including ultraviolet (UV) light to reduce organic content, and electrodeionization and/or mixed bed ion exchange for demineralization.

- A polishing stage, where the water undergoes rigorous treatment processes including nonregenerable ion exchange, membrane degasification, and ultrafiltration to deliver water that meets the strict UPW specifications.

Ultrapure water differs from deionized water, which is produced by removing most of the mineral ions by ion exchange during the deionization process. Deionization does not reliably remove uncharged organic molecules, bacteria, viruses, or dissolved gases. While deionized water is considered highly purified water and contains little to no mineral ions, contaminants such as dissolved gases, and bacteria and viruses can remain. Deionized water is suitable for many applications, but for applications that require the highest degree of purification, ultrapure water is the most appropriate choice.

Ultrapure Water Applications

Ultrapure water plays a crucial role in processes where the existence of even minimal levels of contaminants can lead to severe repercussions, including many research disciplines such as biology and biotechnology, medicine, pharmaceutical research, semiconductor study, and research and development.

- Ultrapure water plays a critical role in laboratory research and development, as well as in biotechnology laboratories, where contamination in any form could compromise the validity of scientific experiments or the quality of products being developed. Ultrapure water is used in the formulation of sterile solutions, media, and reagents and for cleaning laboratory equipment to prevent cross-contamination.

- Ultrapure water plays a crucial role in the development of pharmaceutical products. Its primary function is to prevent contamination and safeguard the quality of ingredients, ensuring the end product is effective and safe for human consumption. In laboratory testing procedures and quality control, ultrapure water is indispensable. It is used for tasks such as dilution of samples or solutions, instrument calibration, and the cleaning and sterilization of laboratory equipment and surfaces.

- Ultrapure water is used to clean semiconductor wafers, printed circuit boards, and liquid crystal panels during the manufacturing process to ensure they are free of dirt and fine particles that could reduce their performance or that of other sensitive components.

- Ultrapure water is used to clean and sterilize surgical instruments, medical devices, and other equipment used in procedures where contamination could lead to infection that could compromise the health and well-being of patients. Ultrapure water is also used as Water for Injection.

Why Is Ultrapure Water Needed in Lab Settings?

Pharmaceutical, life science, and R&D laboratories conduct critical clinical tests and laboratory experiments whose outcomes could be compromised by the presence of unwanted contaminants. Tap water may be safe for human consumption, but it still contains harmless impurities such as minerals or trace levels of bacteria that can jeopardize the accuracy of these results or the quality of pharmaceutical products. It is, therefore, essential that only water of the highest quality be used when manufacturing pharmaceutical products or conducting laboratory experiments, tests, and analyses. Some examples of why this is so important are discussed below:

Cell and Tissue Cultures: When cells are artificially cultivated in a controlled laboratory setting, the cell culture needs to be supplied with water and essential nutrients to facilitate growth while taking rigorous precautions to prevent the culture from becoming contaminated with potentially damaging pollutants such as heavy metal ions, bacteria, and endotoxins. Ultrapure water serves this purpose, ensuring the cell culture gets the water and nutrients it needs to flourish without being compromised.

Genetic Testing and Sequencing: When conducting DNA sequencing of biological samples, the water used during the sequencing process must adhere to rigorous quality standards. Contaminants such as bacteria, ions, nuclease, and organic matter can interfere with the DNA sequencing process or adversely affect results. As the DNA sequencing process amplifies DNA, any unwanted DNA — for example, from bacteria — will also be amplified, potentially compromising the sample and the study’s results.

Chromatography: Chromatography is an effective method for identifying components of a liquid or gas mixture. Ultrapure water is used as a reagent in this process because it doesn’t contain contaminants such as bacteria, ions, organic compounds, and solid particles that can introduce background noise and potentially compromise the accuracy of results.

How Can MECO Support Universities?

The MASTERpak™ MICRO excels in university labs, providing a compact design, enhanced sustainability, and a reduction in operating expenses.

MECO’s MASTERpak™ MICRO is a turnkey water purification system that produces high-quality ultrapure water that meets global pharmacopeia and laboratory standards, including standards for Water for Injection. The MASTERpak™ MICRO’s small footprint, low noise output, and cost-efficient operation make it the ideal solution for university laboratories that need an affordable and sustainable source of ultrapure water. The benefits of the MASTERpak™ MICRO include:

Small Footprint: The MASTERpak™ MICRO’s compact design takes more than 40% less space while producing 60% more water than similar industry solutions. In a university laboratory environment where space is often limited, this offers a huge advantage, freeing up valuable space for other uses.

Low-Noise Output: The MASTERpak™ MICRO, with a noise level of just 60 dB, is the quietest ultrapure water treatment system on the market. This quiet operation makes it well suited to a university setting, where noisy machinery could be a major distraction. The MASTERpak™ MICRO can be positioned anywhere on campus, including alongside an office, without impeding the concentration of academics or students working or studying nearby.

Reduced Operating Expenses: The MASTERpak™ MICRO has been designed with sustainability in mind. It features water and energy-saving mechanisms that minimize water and electricity consumption and maximize water recovery. It also uses fewer chemicals, resulting in lower operating expenses.

Contact MECO for Water Purification Solutions

With more than 90 years of experience providing innovative, cost-efficient water purification solutions, MECO continues to support university research and development laboratories and the pharmaceutical industry by providing cost-effective water purification solutions to support their research. Contact MECO today to learn more about our water purification solutions and how they can benefit your lab.