Advances in Vapor Compression Technology

There are various methods used to produce high purity water for the pharmaceutical and biotech industry. Vapor Compression (VC) distillation plants have seen widespread use in the production of bulk Purified Water (PW) and Water For Injection (WFI). Two principal reasons for using VC technology are the high thermodynamic efficiency of the process and the opportunity to use a simplified pretreatment system.

We developed this blog to aid you in making an intelligent comparison of VC systems based upon design and construction techniques. We hope you will note the details that add to the value of a MECO vapor compression distiller and insist upon them in any system you select.

This article presents the advancements in vapor compression technology and how these advancements affect the efficiency and reliability of the equipment.

Vapor Compression: How It Works

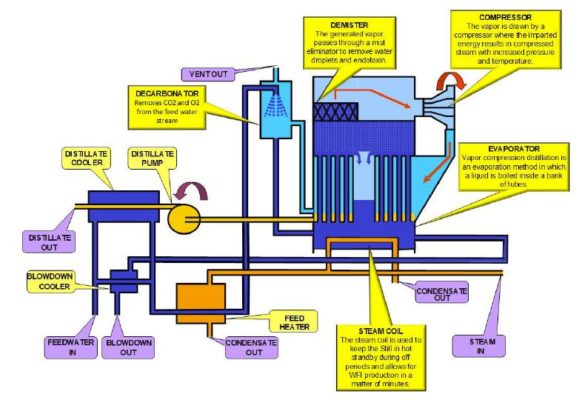

Vapor compression distillation is an evaporation method in which a liquid is boiled inside a bank of tubes at slightly above 212ºF (100ºC) to create vapor. The vapor then passes through a mist eliminator to remove any water droplets. The pure vapor is withdrawn by a compressor where the imparted energy results in compressed steam with increased pressure and temperature. The maximum temperature achieved through this vapor compression process is approximately 224ºF (107ºC). The high energy compressed steam is discharged in the evaporator, on the outside of the tube bank, where it gives up most of the energy (latent heat) to the water inside the tubes. More vapor is generated and the process is repeated. The condensate (distilled water) is withdrawn by the distillate pump and is discharged through a two stream heat exchanger. The excess feedwater that did not evaporate (blowdown) is also pumped through an exchanger. Both the distillate and blowdown are cooled and the feedwater is pre-heated prior to entering the evaporator. These exchangers minimize energy consumption of the system and eliminate the need for additional cooling water. The system operates continuously once started and produces water meeting the requirements for Purified Water and Water for Injection with a conductivity of less than one microsiemen per centimeter.

Vertical Evaporator

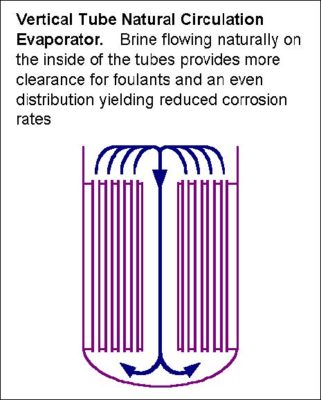

MECO’s evaporator is a vertical tube natural circulation design. The vertical arrangement allows the feed water to be on the inside of the tubes yielding numerous benefits to operation and maintenance. Feedwater boiling on the inside of a tube allows the flow to travel up the inside diameter of the tube and return to the base of the evaporator via an internal downcomer. This type of system is called a natural circulation evaporator design. Vapor compression systems that employ a horizontal tube evaporator design must force circulation by using pumps and spray nozzles, which increase both operating and maintenance costs.

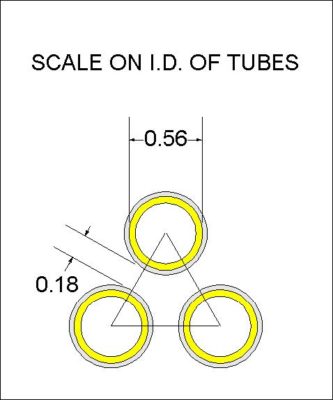

Feedwater should be adequately pretreated with dechlorination, reverse osmosis, deionization or softening to prevent scaling and corrosion of any evaporative system. However, upsets in pretreatment can occur and when they do, the benefits of a natural circulation evaporator with feedwater on the inside of the tubes become obvious. First, there are no spray nozzles to become clogged, so deposition of scale will form evenly along the tube wall in a natural circulation evaporator. As a result, the removal of scales, via cleaning solutions, is done uniformly throughout the tube surface. Second, the clearance for fouling on the inside diameter (ID) of the tube is substantially greater than the clearance for foulants between the outer surface of tubes in a horizontal bundle. Natural circulation vertical designs simply will not operate to the point where scale totally blocks the ID of the evaporator tube, a protection inherent in the vertical design.

Besides the obvious maintenance problems associated with spray nozzles and circulation pumps, there can be operational problems inherent in the design of a system which sprays feedwater on the outside of a horizontal tube bundle. Spray systems typically deposit scales in isolated areas leaving other areas of the tube bundle exposed. Subsequent chemical cleanings attack bare metal while removing isolated scale deposits.

It is possible for horizontal designs to have scale bridge the gap between tube walls therefore “bricking” the tube bundle. Mechanically cleaning an evaporator is rare, but if the occasion arises, foulants within the feedwater on the ID of a tube can be brushed out from a vertical tube evaporator. It is physically impossible to mechanically clean foulants from the outside of a tube within a

horizontal tube bundle.

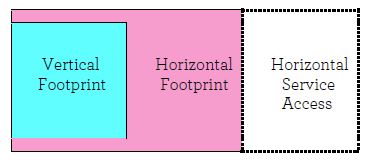

Footprint

The space requirements for vertical vs horizontal evaporation systems can be dramatically different. The vertical design minimizes floor space requirements. Also, vertical evaporator tubes do not require additional floor space for service clearance in situations where removal and cleaning of evaporator tube bundles is required. As your facility continues to expand, and additional stills are added, the additional costs associated with providing adequate floor space for this equipment should be considered.

Tubesheets

All MECO vapor compression stills use a straight tube design requiring two tubesheets with the tubes rolled and expanded at both ends. It is more costly to do it this way, but there are several benefits. Any of the tubes can be replaced without disturbing adjacent tubes or scrapping the entire bundle and tubesheets. Also, this design allows MECO to provide an exterior finish of 25 RA or better on the surface area in direct contact with the distillate.

The use of two tubesheets fixes the bundle at both ends eliminating the need for baffling required in single U-Tube tubesheet designs. Baffling can be a source of crevices, surface scratches and subsequent corrosion problems.

MECO has experience with both horizontal and vertical designs. Our decision to only offer a vertical design evaporator on our stills may cost us more (we offer both vertical and horizontal evaporators on our pure steam generators), but we believe the benefits outweigh the additional costs in this situation.

Straight Tube Design

The MECO straight tube design eliminates the need to bend the tubes inherent in U-Tube design. In the absence of heat treating, bending of the tubes imparts residual stresses which makes the bundle more susceptible to corrosion and disrupts the surface finish at the bends.

Tubing

The requirements and choices for evaporator tubing can sometimes be confusing and do have an impact on the cost associated with manufacturing quality stills. MECO evaporators can utilize seamless or welded tubing (ASTM A-269). We typically recommend the welded bright annealed tube, which is standard, because of its naturally superior surface finish. It is a little known fact that tubing which is welded and bright annealed has a normal surface finish less than 20 Ra both internally and externally. Evaporators that utilize U- Tube bundles are limited to the use of seamless tubing considering the stresses imparted through bending. Seamless tubing must be mechanically polished and/or electropolished to achieve the same level of surface finish normally available in a welded bright annealed tube. The benefit of the annealing process is that the tubing is stress relieved, and in the absence of any bending, is less susceptible to the effects of stress related corrosion or failure.

Corrosion Protection

Stainless steels are susceptible to stress corrosion cracking (SCC). Several factors influence an evaporators susceptibility to SCC. These factors are typically a function of the operating environment (such as water quality and operating temperature) along with construction materials and techniques. MECO’s process and evaporator design takes into account the effects of the operating environment. Specifically, MECO stills have a deaerator in the feedwater stream to remove oxygen and carbon dioxide before their harmful effects have a chance to impact the evaporator. Experience has taught us that vent condensers are more susceptible to corrosion given the propensity for non-condensable gasses to collect and attach to the relatively cooler surfaces and attack welds and crevices. The continuous washing of the tube surface in the operation of the natural circulation design prevents the accumulation of chlorides which would otherwise form concentration cells and induce SCC. Tubing within the MECO evaporator is heat treated through annealing eliminating residual stresses that may have formed during the manufacture of the tube. Finally, prior to shipment, each MECO plant is thoroughly cleaned, passivated and documented in accordance with strict procedures.

Construction

Similar to design choices, construction materials and techniques vary, but should embody only the highest quality. MECO builds to cGMP construction standards and segregates all stainless steel fabrication in a facility with a work force dedicated solely to the pharmaceutical industry. There is no mixing of tools, work stations or people. The manufacture of WFI Stills is not a once in a while effort or a sideline business for us. At any given time, our backlog is filled with pharmaceutical water systems in production for the leaders in the industry. As you would expect, everything is done with qualified personnel, precision tools calibrated to exacting specifications and documented in accordance with written procedures.

Compressors

One feature of an efficient VC system utilizes a compressor that generates a low differential pressure (and hence vapor temperature) to drive the distillation process at the optimal heat transfer coefficient. A low differential pressure across the compressor contributes to low electrical energy consumption in the VC cycle. Three principal types of compressors have been used until the variable speed directly driven centrifugal compressor was developed. The belt driven approach, while simple and practical is a source of maintenance as is the re-circulating oil system. The physical configuration of the industrial fan with its external ducting, large support base, casing, impeller, intermediate bearing block, and various appurtenances contributes to a high capital cost. The smaller compressor designs had similar albeit different capital expenditures on belts, sheaves, belt guards, and motor stand. The force feed lube oil systems on both designs are a significant subsystem.

The following objectives were considered with the design of a modern variable speed direct-drive compressor:

- Sustainability

- Reduce maintenance

- Improve reliability

- Simplify operation

- Reduce capital costs

The attributes of the smaller higher speed compressors were desirable, but the use of a transmission system, such as belts or gears to increase the speed was not. Likewise, an alternative to the forced feed oil lubrication systems also would be desirable. It became apparent that a variable speed motor operating at elevated speeds directly coupled to the small compressor fluid end previously described would offer

several advantages and design challenges. Since none were found commercially available to suit the required duty, a new system to meet the specific needs was developed. By coupling the fluid end of the centrifugal compressor with a series of stator and rotor designs, a diverse range of performance characteristics were achieved. These were matched with variable frequency drives suitable for the application. The application of a variable speed motor and drive offers several benefits. Principal among these is the ability to vary the distillate production and the associated power consumption. This becomes important since the operational costs of distilling water are many times the first cost of the

plant in considering the life of the equipment. There are additional power savings by eliminating transmission systems, such as belts or gears and intermediate bearing housings.

The MECO GII Centurbo™ Compressor

The MECO GII Centurbo™ compressor design influences energy consumption, system reliability, maintenance and adherence to regulatory guidelines. The GII technology employs a directly driven compressor impeller via a variable speed motor and drive. The result is a system with higher reliability, lower maintenance, better efficiency and less noise. The GII compressor eliminates the need for transmission systems such as couplings, belts and gears. Also eliminated is the circulating oil system with its filters, coolers, pumps and associated valves and instrumentation. The GII Centurbo™ compressor operates at less than 80dBA from one meter away and is the quietest compressor for the application on the market.

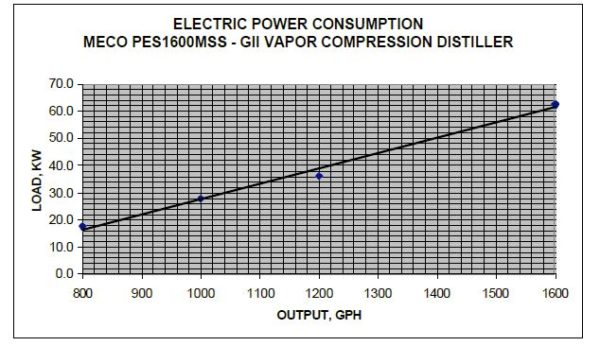

Perhaps most important is the GII compressor’s impact on energy consumption. The GII technology enables a variable output of your distiller within a given maximum capacity. Instead of starting and stopping to produce a fixed output, MECO GII distillers have a variable output to meet diminished or increasing needs for production. As you can see from the chart below, a 25% reduction in production capacity translates to a 40% reduction in compressor power.

Improvements in compressor design have increased reliability, decreased maintenance, noise, energy consumption, installation costs, and simplified the operation of the vapor compression process. The integration of variable speed technology to the improved compressor system has increased the ability to synchronize output with production needs.

FAST START-UP AND HOT STANDBY: HEATING COIL

MECO’s vertical tube VC evaporators have the benefit of utilizing a heating coil within the evaporator combined with an advanced control system for rapid heat-up and hot standby operation. From a cold condition, MECO plants typically come online in 45 minutes and are instantaneously and reliably started from a hot standby condition.

For a more sustainable approach, MECO offers plate heat exchangers if preferred over heating coils. The plate heat exchanger that encompasses a large surface area resulting in an increased rate of heat transfer and lower utility costs.

WATER QUALITY

Non-condensable gasses, such as CO2 and oxygen, if allowed into the evaporator, cause corrosion and blanket heat transfer surfaces, which reduces output and can contribute to higher conductivity. The feed water deaerator strips most non-condensable gasses prior to entry into the evaporator, thus maximizing efficiency and minimizing corrosion.

QUIETER OPERATION

Operating at only 72 – 85 dBA, MECO’s GII Centurbo™ Compressor is quiet. You don’t need acoustic walls or personal hearing protection. Because people in adjoining spaces aren’t affected, you can position your water room just about anywhere, even right next to an office. Your water room works better and is a better place to work.

Download a Copy Here

Electricals, Instruments and Controls

MECO’s Automation Group designs, installs and tests a variety of systems covering some complex applications, including the overall water treatment facility. We are experienced in retrofits and upgrades of older systems and variable speed systems that have substantial benefits to the industry. A first out safety and alarm indicating system is standard on all units. The control panel houses main and individual circuit breakers, motor starters, contactors, and control wiring. MECO pioneered the use of PLC controls in pharmaceutical distillation applications decades ago and is today leading the way in PC based controls and variable speed systems that have substantial benefits to the industry.

Quality

MECO has been ISO 9001 certified for nearly 25 years. Our commitment to providing the best quality products and services for our clients continues to be reflective of this. We set our standards high and we consistently meet our objectives. Of course, we are not new with respect to achieving certification. We have been certified to U.S. Military standards MIL-Q-9858A, MIL-I-45708, the ASME, NEMA, IEC codes. We also possess CE and UL certification.

Service

24 hours a day, 7 days a week, MECO is available to service clients needs. Considering that we have the largest install base of vapor compression stills worldwide, it only stands to reason that we would have the most experienced and talented service organization in the industry. If you are a MECO customer, you know that our service group is proactive, rather than reactive.

Our newest technology innovation, MECO smartANALYTICS™, is a data profiling and predictive maintenance service that allows MECO engineers to monitor your water systems’ performance in real-time as well as proactively schedule maintenance, optimize operations and make recommendations on sustainable best practices. Additional benefits of incorporating smartANALYTICS™ into any water system include optimized system performance, decreased utility costs, reduced energy usage, and reduction of consumables. By preventing production interruptions and identifying opportunities to reduce water waste, MECO smartANALYTICS™ helps minimize the impact on facilities’ water footprint and maximizes pure water recovery supporting facilities’ net zero strategies.

Validation

MECO offers the most comprehensive validation package available in the industry. Hundreds of MECO units have been validated to the most stringent industry guidelines. MECO’s standard validation package includes a comprehensive list of documents to support Site Acceptance Test (SAT), Installation Qualification (IQ) and Operational Qualification (OQ) protocols. Optional validation material is available to suite your specific validation needs. Furthermore, MECO offers a proven FDA validatable SAT, IQ and OQ protocol.

In Summary

No one has invested more in the development of vapor compression distillation than MECO. MECO was the first company to patent the vapor compression technology in 1939. We introduced the vapor compression process to the pharmaceutical industry in 1954. The evaporator design is the heart of the system and culminates from years of experience with other designs. Experience is not something that can be passed along. It is earned through years of dedication and understanding of the science and industry behind a technology. Over the last seven decades, we have garnered a reputation and a list of customers and references that is second to none in the industry. If you would like to request more information regarding our vapor compression distillation & vapor compression desalination technology or to get in touch with a MECO representative, fill out our form below!

Get in Touch