How Water Purity Impacts the Food and Beverage Industry

Water quality has a substantial impact on food and beverage industry manufacturing processes due to its dual role as both a utility and an ingredient. To ensure a safe, reliable, and consistent product, industry leaders invest in industrial water purification systems that meet regulations and help ensure a quality product.

Consumer Safety in The Food and Beverage Industry

Water is both an active ingredient in many products and a utility medium critical to cleaning and sanitation in the food and beverage manufacturing industry. In other words, a trustworthy water source is a key factor in a trustworthy product. When special care is not taken to protect the water supply, manufacturers run the risk of creating a tainted product, which can take a toll on their finances and reputation.

An industrial water purification system offers manufacturers and consumers peace of mind by eliminating toxins and biological material that can impact the safety of food and beverage products.

VIEW OUR FOOD & BEVERAGE INDUSTRY SOLUTIONS

Product Reliability

The quality of municipal and natural water sources such as lakes, oceans, or rivers varies according to mitigating circumstances. One treatment method is not suitable for all sources. Water purification systems that treat water from numerous sources must use different treatment techniques. They may also produce various qualities of pure water.

In order to combat the inconsistencies in feed water sources, food and beverage manufacturers utilize industrial water purification technologies to purify the raw water into purified water or ultra-pure water quality for their operations. This is a key advantage in making a reliable product.

Quality

When ultra-pure water is a key ingredient in a product, that facility’s water supply has a profound impact on the way the products taste. Chloride, sulfate, and other anions negatively affect the flavor of wine, beer, and other beverages. Biological material will also alter the flavor composition. Water that has not been properly treated can react negatively with other ingredients in food or beverage products and create undesirable odors, colors, and tastes or a lack of consistency across these aspects.

Reverse osmosis and other innovative water purification technologies ensure the purest water for product development. Some common water treatment processes in the food and beverage industry include:

- Distillation: Vapor compression distillation involves boiling water to create high-pressure compressed steam, which subsequently becomes purified condensate. This water treatment method can serve applications where Purified Water is necessary for use as an ingredient or for direct contact with consumable products.

- Carbon filtration: Carbon filtration removes chlorine and chloramines from water, making it more suitable for various applications in a food processing facility. This process also facilitates more thorough treatment. When used with reverse osmosis, carbon filtration keeps the membranes free from clogged debris so that more contaminants are caught.

- Water softening: Water softeners eliminate ammonia and minerals that cause hardness. This food and beverage industry water treatment provides facilities with soft water for cleaning, food processing, and maintaining consistent beverage taste and quality.

Water Purification Equipment

It is common to overlook the impact that water has on the life span of manufacturers’ equipment. Water alkalinity, sediment, organics, and minerals can all take a toll on utilities. From limescale buildup to corrosion, water-related damage can reduce operational efficiency and increase the cost of maintenance and repairs. Biofilms on equipment can facilitate microbe-induced corrosion, contaminate the water supply, and significantly reduce the efficiency of components like heat exchangers.

A water purification system keeps facilities operating efficiently and also increases the longevity of essential equipment, which can mean major long-term cost savings.

Sanitation

Food industry companies rely on water free of impurities and microorganisms to wash produce and food processing equipment. Equipment that sees frequent use and contact with food items, such as boilers, packing machines, steamers, and dishwashers, must regularly undergo sanitation to avoid contamination that can harm end users or employees.

Filtered and treated water is vital for proper sanitation and helps food producers avoid introducing more contaminants during the cleaning process. Sanitation water quality standards also apply to equipment that is not washed in areas where food production occurs, such as transport and storage vehicles.

Steam Generation

Steam serves many purposes in the food and beverage sector, from packaging to sterilization. Its quality can decrease in various ways, such as boiler carryover, the presence of gases like ammonia and carbon dioxide in feedwater, and excess chemical usage in steam feedwater. Because of steam’s many potential uses in a facility, cross-contamination is also more likely.

Maintaining steam feedwater quality helps prevent issues like equipment scaling and corrosion, foaming in the steam boiler, and high chemical amounts in the produced steam.

Wastewater Regulations

When a food or beverage company disposes of water used for processing their products, they must ensure this wastewater meets relevant federal and local regulations to avoid contaminating the environment or falling out of line with compliance requirements. Although this wastewater does not need to meet the same purity standards as water used in food processing, it should not have an excess of chemicals or other impurities that can harm people or the environment.

For example, the typically high organic load of food industry wastewater — up to 10 times higher than wastewater from municipal applications — can contribute to issues like eutrophication. Techniques like nanofiltration and carbon filtration can combat these high organic material levels for cleaner wastewater.

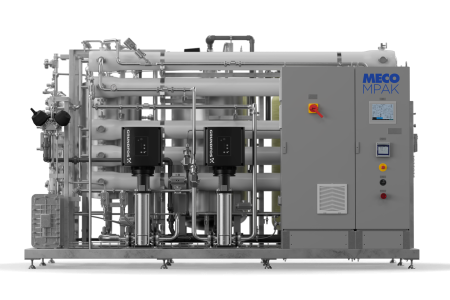

MECO ensures pure water for critical manufacturing processes in the food and beverage industry.

The MECO worldwide portfolio includes the broadest range of engineered products for purified water, distilled water, and pure steam. Our products are used to manufacture the world’s bottled water, sodas, sports drinks, beer, spirits, and food products. From pretreatment solutions such as multi-media filtration, carbon filtration, water softening, and reverse osmosis to production equipment vapor compression, RO/EDI, and pure steam to storage and distribution, we offer a variety of solutions for the industry’s ultra-pure water needs.

Contact MECO today for questions about innovative water purification solutions for the food and beverage industry.